Yes, helps clarify the DC behavior of the system. However, it doesn't appear to model the AC behavior of the circuit i.e. the source of the RF signal you detected. Perhaps the simulator has a pulse source available that could be applied to the shorting switch function. Sweeping the pulse rate should show one or more resonant peaks in the waveforms.

The simulator does have a pulse source. I tried to come up with something acceptable that could work as an equivalent, but I'm not sure if this one would simulate correctly what is going on. You can tweak the parameters, either through the sliders on the right or by double clicking the components. As it is, it doesn't look like it would resonate at very high frequencies, in the RF range, but the equivalent circuit could possibly be improved (the main issue is that it's truly trying to simulate the actual components used, which might not be the best approach here).

(Link to the simulation)

(Second version with a shorter simulation timestep)

To explore the RF behavior, I would like to replicate your cell. Could you please supply some physical dimensions and details of materials used.

Thanks for attempting to replicate the observations. You should be able to see at least some of them (the non-LENR-related ones).

The steel electrodes have been selected more or less randomly from a container of steel brackets of various sorts, basing on these criteria:

- Same overall characteristics for both of them

- Elongated narrow flat shape

- Convenient to use in the glass jar I planned employing for the tests.

- Ferromagnetic properties

- I thought this would be useful for magnetic field concentration or if I decided to keep the entire assembly together with magnets like I did with the coin and washer combo, which I eventually didn't.

- Pre-drilled holes

- I thought this would facilitate the diffusion of electrolyte solution into the narrow gap.

- Sufficiently large thickness

- For rigidity and longer lifetime against erosion/corrosion processes.

The steel brackets I used were initially coated or anodized with some sort of thin (micron-thick) yellowish layer that would appear to react more vigorously in a caustic solution than the steel used for the bulk during the initial electrolytic attempts. I eventually completely removed that with immersion for about 15-20 minutes in liberally diluted ambient-temperature solution of 10% HCl, grocery-store grade. Successive cleaning baths under similar conditions have been performed on different occasions, but that layer was already long gone.

The initial dimensions for both electrodes were:

- Width: 14mm

- Thickness: 2 mm

- Length: 140 mm

I don't think that the shape of the electrodes is critical, but I thought that them being thick would help.

Since the pieces are strongly ferromagnetic and likely of cheap origin, but don't appear to corrode easily, they are probably composed of ferritic stainless steel or some sort of chrome steel. They do not bend very easily, but the thickness might be a factor here.

On various occasions (typically before a new experiment session began) I used dry 180-grit brown sand paper to roughen their active surface, or the same under wet conditions and less energetically in warm water to clean them up.

I thought that for this sort of experiments where I'm not specifically using magnets to hold the electrodes together, SS316 (as typically used in HHO cells, by the way) or pieces composed of different materials (e.g. Nickel and Copper, Nickel and Aluminium, etc) could potentially be more useful, especially if electrode polarity is periodically reversed or if AC is used. However I haven't tried that yet and I don't think I have suitable pieces of different materials laying around other than old coins (from various countries).

The jar used has roughly these dimensions:

- Inner diameter of top opening: 32 mm

- Outer diameter at base: 42 mm

- Height (without lid): 50 mm

- Capacity: nominally 25 ml

Feel free to ask for any other detail I might have missed.

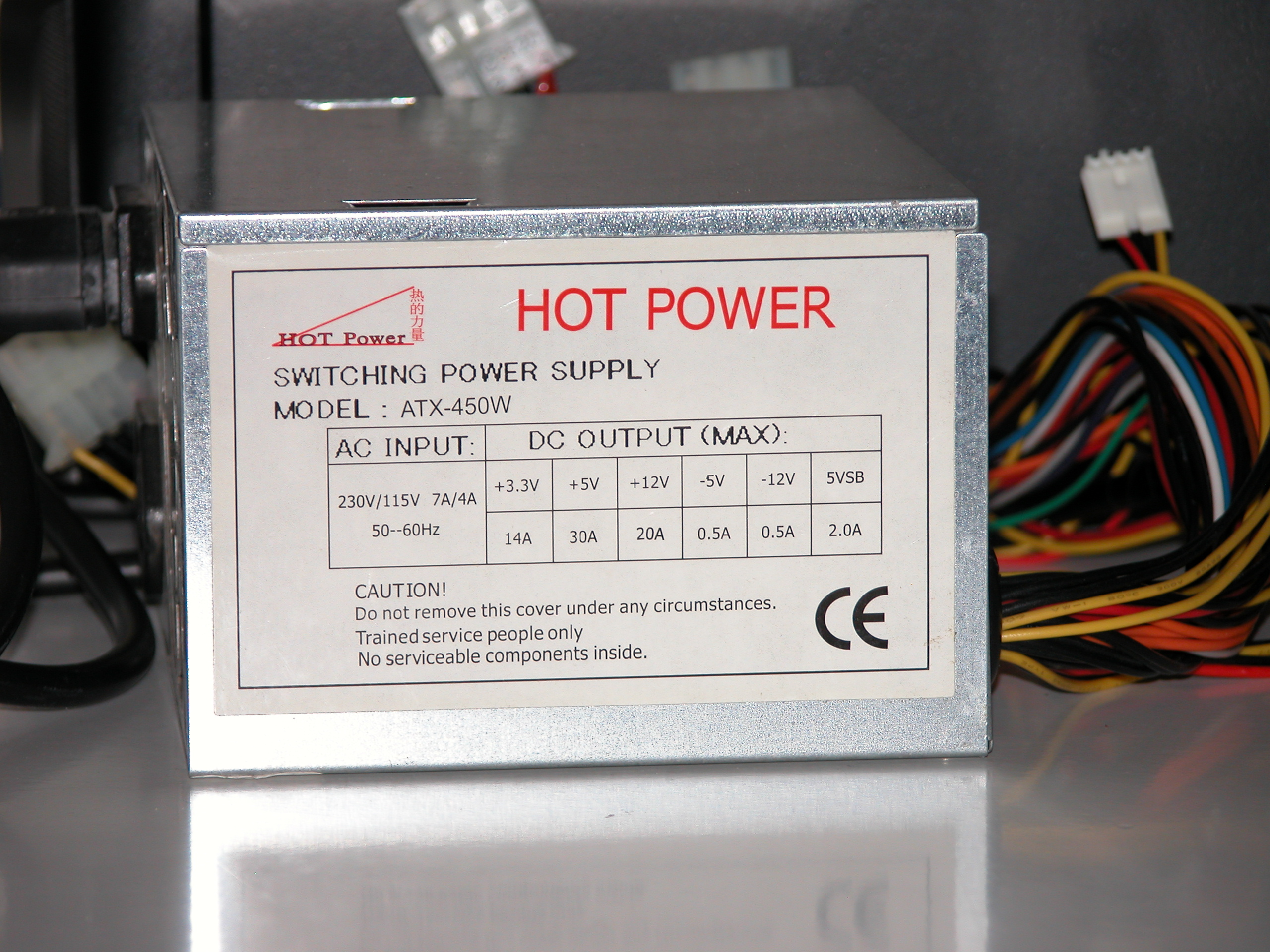

Because the 1.3 kHz audio modulation might originate in the power supply, it would be helpful to have the make and model for that as well.

The one I used is a cheap, decade-old chinese ATX 12V power supply normally intended to be used with desktop PCs. It's likely that the output gets dirty when the load is unbalanced, as is the case with many other cheap computer PSU. Close to the current limit of 20A (I'm guessing) at the 12V rail, voltage is not within ATX specifications anymore and drops to about 8.5V, although when such sound was emitted by the cell, PSU did not seem to be close to the limit yet.

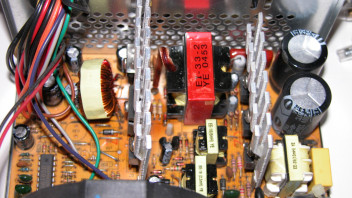

EDIT: here are a few more photos of the power supply.